Introduction CAN Stand For in CAN Bus

CAN Stand For in CAN Bus : If you’ve ever come across the term CAN bus in automotive or embedded systems, you might wonder, “What does CAN stand for in CAN bus?” This beginner-friendly article will answer that question, along with explaining the basic concept of the CAN bus and its importance.

What Does CAN Stand For in CAN Bus?

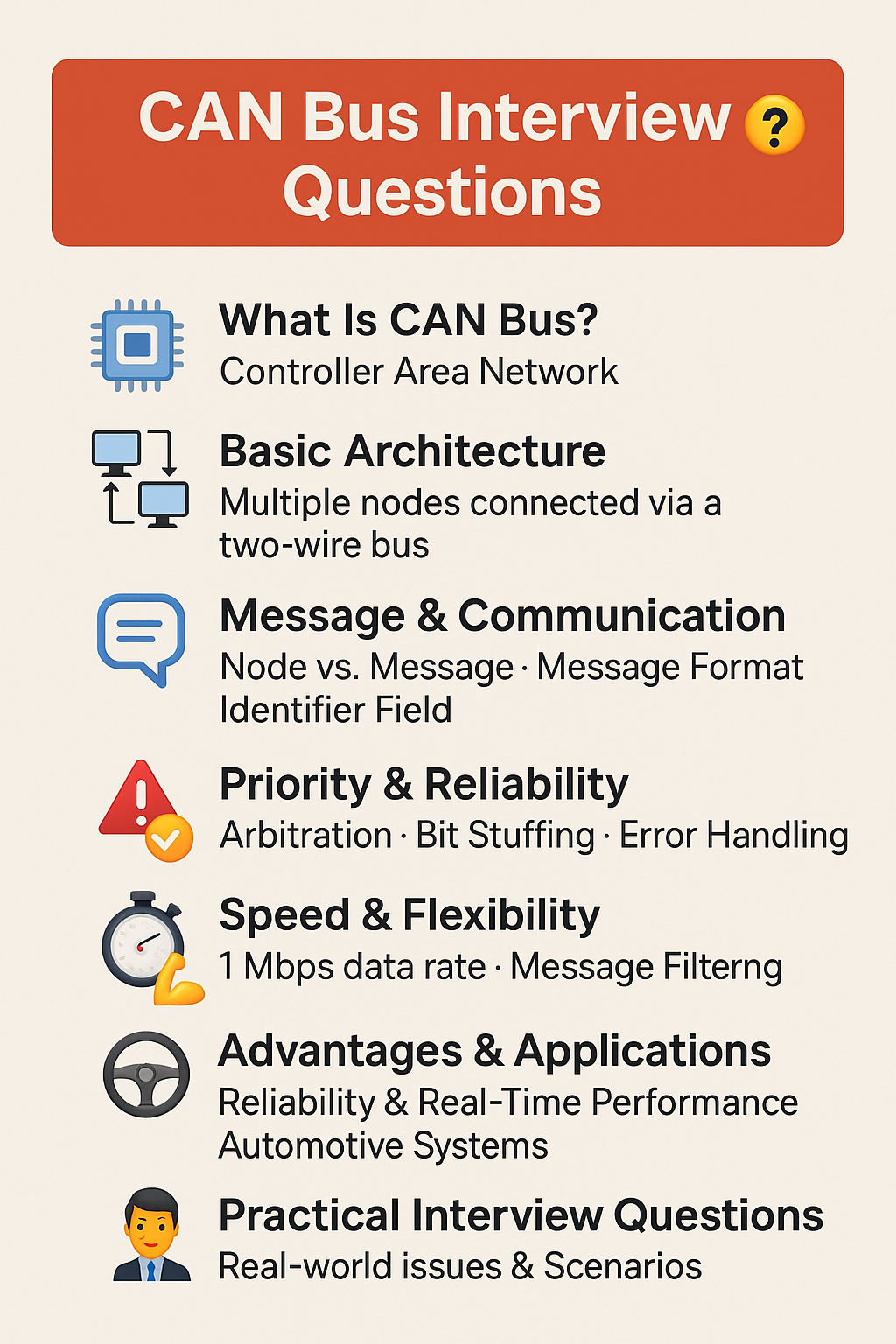

CAN stands for Controller Area Network.

The CAN bus is a communication protocol that allows multiple microcontrollers and devices (or nodes) to communicate with each other without the need for a central host computer. It was developed by Robert Bosch GmbH in the 1980s, primarily for use in automobiles, but it is now used in many industrial and automation applications.

Why Is It Called a “Bus”?

In electronics, a bus is a communication system that transfers data between components.

So, a CAN bus is essentially a Controller Area Network communication bus — a shared pathway that connects various electronic control units (ECUs) in a system.

Key Benefits of CAN Bus

- ✅ Efficient Communication: Reduces the complexity of wiring by allowing devices to share one common data line.

- ✅ Robust & Reliable: Designed to work in noisy environments like vehicles and factories.

- ✅ Real-time Performance: Supports priority-based message handling.

- ✅ Cost-effective: Reduces wiring and improves system scalability.

Where Is CAN Bus Used?

- 🚗 Automotive Systems – Connecting engine control units, airbags, ABS, lighting, and infotainment.

- 🏭 Industrial Automation – Linking sensors and actuators in factory settings.

- 🚜 Agricultural Machinery – Used in tractors and harvesters for precision control.

- 🏥 Medical Equipment – For connecting various modules safely and reliably.

Summary

So, to answer the question “What does CAN stand for in CAN bus?” — it stands for Controller Area Network.

This powerful communication protocol plays a critical role in modern embedded systems, especially in vehicles and industrial automation. Its ability to allow multiple devices to talk to each other efficiently and reliably makes it a standard choice in many real-world applications.

Frequently Asked Questions (FAQ): What Does CAN Stand for in CAN Bus?

1.What does “CAN” stand for in CAN Bus?

CAN stands for Controller Area Network. It’s a communication protocol that allows microcontrollers and devices to communicate with each other without a host computer, especially in automobiles and industrial automation systems.

2.Who developed the CAN protocol?

CAN was developed by Robert Bosch GmbH in 1986 for automotive applications.

3.Is CAN bus only used in cars?

No! While CAN Bus started in vehicles, it’s also widely used in industrial automation, agriculture, medical devices, marine electronics, aviation, and many other fields.

4.What is the data rate of CAN bus?

Standard CAN supports speeds up to 1 Mbps. The newer CAN FD (Flexible Data-rate) supports even higher speeds and larger data payloads for modern applications.

5.How many devices can connect to a CAN bus?

Up to 112 nodes can be connected to a CAN bus, but the exact number depends on the network’s electrical design and bus length.

6.Why is it called a “Bus”?

The term “bus” refers to a communication system that transfers data between components. In CAN Bus, all nodes share the same communication line (the bus).

7.Where is CAN Bus used?

Besides cars, CAN Bus is used in:

- 🚗 Automobiles (ECUs, sensors, ABS)

- 🏭 Industrial Automation

- 🚜 Agricultural Machines

- 🚢 Marine Electronics

- 🛩️ Aviation Systems

- 🏥 Medical Equipment

8.How does CAN Bus improve communication in vehicles?

CAN Bus enables:

- Real-time communication

- Reduced wiring complexity

- Built-in error detection and fault confinement

- Multi-master communication

- Operation in electrically noisy environments

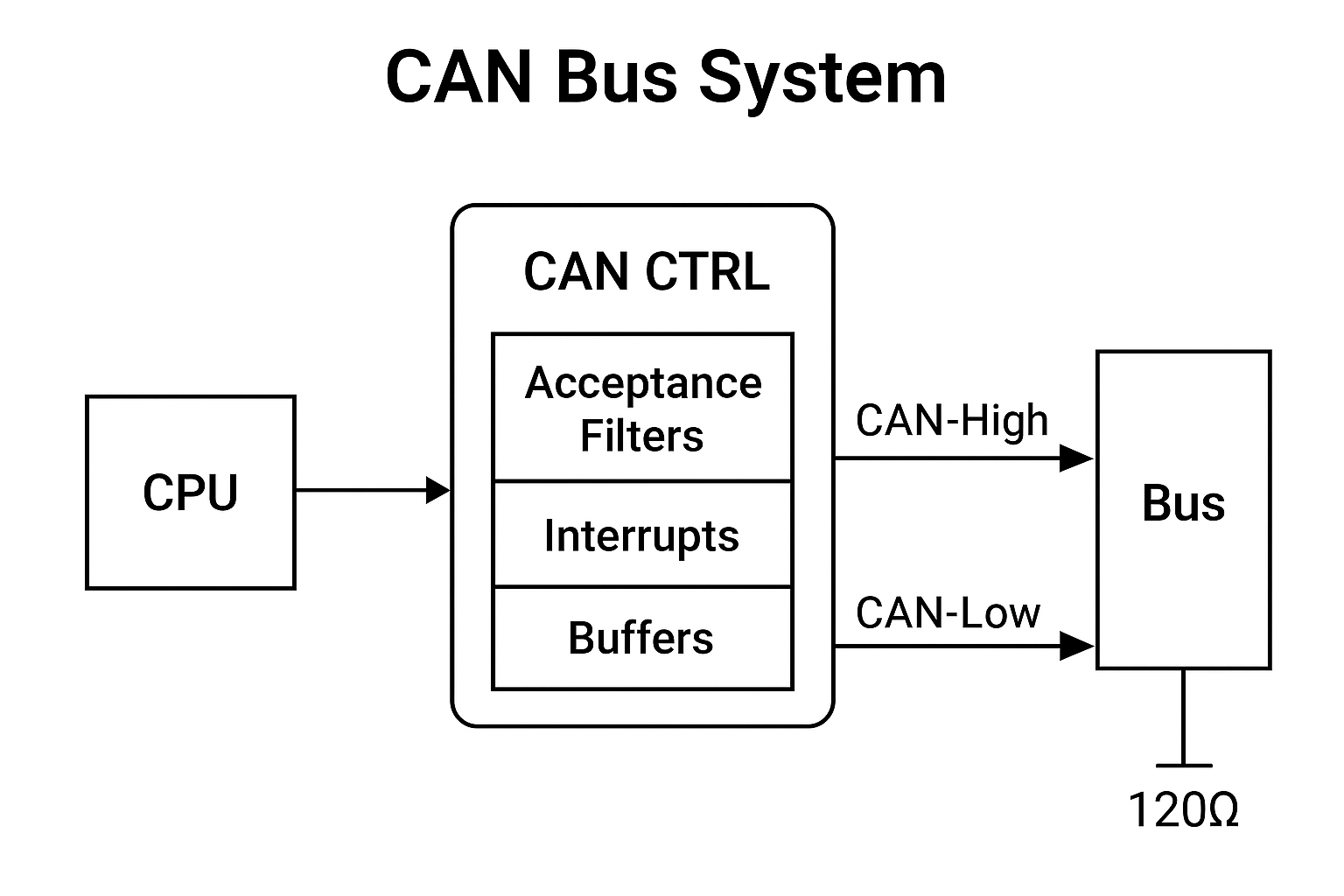

9.Is CAN a hardware or software protocol?

It’s both! CAN protocol is implemented in hardware (CAN controllers and transceivers) and software (CAN drivers and protocol stack).

10.What are the advantages of using CAN?

Key benefits include:

- Robust error handling

- Priority-based message arbitration

- Scalability with multiple nodes

- Efficient bandwidth utilization

11.Are there different versions of CAN?

Yes! Main versions include:

- Classical CAN (original standard)

- CAN FD (Flexible Data-rate for faster and larger messages)

- CAN XL (next generation with higher speed and payload capacity)

12.How is CAN different from other protocols like I2C or SPI?

- CAN supports multi-master, long-distance, robust communication

- I2C is simpler, used for short-distance, board-level communication

- SPI is fast, point-to-point, but usually for short-range use

13.Do I need a microcontroller with a CAN interface to use CAN Bus?

Yes, either a microcontroller with an integrated CAN controller or a setup with an external CAN controller (e.g., MCP2515) plus a CAN transceiver is required.

You can also Visit other tutorials of Embedded Prep

- Multithreading in C++

- Multithreading Interview Questions

- Multithreading in Operating System

- Multithreading in Java

- POSIX Threads pthread Beginner’s Guide in C/C++

- Speed Up Code using Multithreading

- Limitations of Multithreading

- Common Issues in Multithreading

- Multithreading Program with One Thread for Addition and One for Multiplication

- Advantage of Multithreading

- Disadvantages of Multithreading

- Applications of Multithreading: How Multithreading Makes Modern Software Faster and Smarter”

Mr. Raj Kumar is a highly experienced Technical Content Engineer with 7 years of dedicated expertise in the intricate field of embedded systems. At Embedded Prep, Raj is at the forefront of creating and curating high-quality technical content designed to educate and empower aspiring and seasoned professionals in the embedded domain.

Throughout his career, Raj has honed a unique skill set that bridges the gap between deep technical understanding and effective communication. His work encompasses a wide range of educational materials, including in-depth tutorials, practical guides, course modules, and insightful articles focused on embedded hardware and software solutions. He possesses a strong grasp of embedded architectures, microcontrollers, real-time operating systems (RTOS), firmware development, and various communication protocols relevant to the embedded industry.

Raj is adept at collaborating closely with subject matter experts, engineers, and instructional designers to ensure the accuracy, completeness, and pedagogical effectiveness of the content. His meticulous attention to detail and commitment to clarity are instrumental in transforming complex embedded concepts into easily digestible and engaging learning experiences. At Embedded Prep, he plays a crucial role in building a robust knowledge base that helps learners master the complexities of embedded technologies.