A multimeter is a must-have tool for electronics beginners. It helps you measure voltage, current, resistance, and continuity, and is essential for diagnosing and troubleshooting circuits.

1. Understanding the Parts of a Multimeter

Most digital multimeters (DMMs) include:

- Display – Shows readings (e.g., voltage, current).

- Dial (selector knob) – Lets you choose what you want to measure: V (voltage), A (current), Ω (resistance), etc.

- Ports – Usually three:

- COM (common) – Black probe goes here.

- VΩmA – For voltage, resistance, and small current (milliamps).

- 10A or 20A – For measuring larger currents.

2. How to Set Up the Multimeter

- Insert probes:

- Black probe → COM

- Red probe →

- VΩmA for voltage, resistance, small current.

- 10A port for high current (more than 200mA).

- Turn the dial:

- Set to V for voltage (DC = ⎓, AC = ~).

- Set to A for current (DC or AC).

- Set to Ω or continuity symbol (🔔 or sound wave) for continuity check.

3. Measuring Voltage

What is it?

Voltage is the potential difference between two points (like pressure in a pipe). Measured in volts (V).

Steps to Measure DC Voltage (e.g., battery, power supply):

- Plug red probe into VΩmA port.

- Turn the dial to DC Voltage (V⎓).

- Touch:

- Black probe to the negative terminal.

- Red probe to the positive terminal.

- Read the display.

Example:

- Measuring a 9V battery should show something close to 9.00V.

Tips:

- Always start with a higher voltage range if manual.

- Multimeters are parallel devices — connect across (not in-line with) the component.

4. Measuring Current

What is it?

Current is the flow of electric charge. Measured in amperes (A).

Important:

To measure current, you need to break the circuit and insert the multimeter in series so the current flows through the meter.

Steps to Measure Current (DC):

- Decide current range:

- Less than 200mA → use VΩmA port.

- More than 200mA → use 10A port.

- Turn the dial to DC Amps (A⎓).

- Break the circuit and insert:

- Red probe toward power supply.

- Black probe toward load (resistor, LED, etc.).

- Power on and read the current on display.

Example:

- LED circuit might draw 15-20mA.

Tips:

- Never measure current directly across a power source — it will short-circuit!

- If unsure about current level, start with 10A port to avoid blowing a fuse.

5. Checking Continuity

What is it?

Continuity means there is a complete path for current flow (no break in the wire or circuit). Measured using the beep or resistance.

Steps to Test Continuity:

- Turn the dial to continuity mode (🔔 or sound symbol).

- Touch probes together → multimeter should beep (circuit complete).

- Test a wire, trace, or fuse:

- Touch each end with a probe.

- Beep = good.

- No beep = open (broken) circuit.

Example:

- Testing a jumper wire or PCB track for breaks.

Tips:

- Useful for checking if a wire or connection is working without knowing voltage.

Bonus: Safety & Best Practices

- 🔌 Always disconnect power before switching modes or ports.

- ⚠️ Double-check port and dial settings before testing.

- 🔋 Test your multimeter on a known battery to check if it works.

- 🚫 Never use the resistance or continuity setting on a live circuit.

Summary Table

| Task | Dial Setting | Red Probe Port | Connection Type | Notes |

|---|---|---|---|---|

| Voltage (DC) | V⎓ | VΩmA | Parallel | Measure across battery/device |

| Current (DC) | A⎓ | VΩmA or 10A | Series | Break the circuit |

| Continuity | 🔔 or Ω | VΩmA | Across path | Beep = good connection |

With Protocol Decoding: UART, SPI, I2C

A Logic Analyzer is a powerful tool that helps you see digital signals over time and decode communication protocols like UART, SPI, and I2C. It’s perfect for debugging embedded systems and microcontroller projects.

1. What Is a Logic Analyzer?

A logic analyzer captures digital signals (0s and 1s) from your circuit and shows them as waveforms on your computer screen. It helps you:

- Visualize what your microcontroller is sending/receiving.

- Decode protocols like UART, SPI, and I2C.

- Debug communication errors or misbehaving devices.

Popular low-cost logic analyzers work with free software like Saleae Logic or Sigrok / PulseView.

2. Basic Components of a Logic Analyzer

- Data Channels – Wires to tap into digital signals (D0, D1, etc.).

- GND Clip – Ground wire to reference signal level.

- USB Connector – Connects to your PC.

- Software – For viewing and decoding signals.

3. General Setup Instructions

Step 1: Connect Wires

- Connect GND of the logic analyzer to GND of your circuit.

- Connect the analyzer’s D0, D1, etc. to the signal lines you want to capture (e.g., TX, RX, SCL, SDA, MISO, MOSI).

Step 2: Launch Logic Analyzer Software

- Use PulseView (open source) or Saleae Logic (if using Saleae device).

- Select sampling rate (e.g., 2MHz or higher).

- Select channels to capture.

Step 3: Capture Data

- Start the capture.

- Trigger the communication (e.g., send data from microcontroller).

- Stop capture and analyze the waveform.

4. Protocol Decoding

Now let’s go through UART, SPI, and I2C decoding step by step.

A. UART (Universal Asynchronous Receiver-Transmitter)

Overview:

- 2 wires: TX (transmit), RX (receive)

- No clock line

- Asynchronous (timing based on baud rate)

Wiring:

- D0 → TX

- D1 → RX

- GND → GND

Setup in Software:

- Add a UART decoder in your software.

- Assign RX line (e.g., D1).

- Set parameters:

- Baud rate (e.g., 9600, 115200)

- Data bits: usually 8

- Stop bits: usually 1

- Parity: usually none

What You’ll See:

- Data bytes sent/received over TX/RX.

- Decoded as readable ASCII or HEX.

Use Case: Debug serial communication between Arduino and a sensor.

B.SPI (Serial Peripheral Interface)

Overview:

- 4 wires:

- MISO – Master In Slave Out

- MOSI – Master Out Slave In

- SCK – Clock

- SS/CS – Slave Select

- Synchronous communication

Wiring:

- D0 → MOSI

- D1 → MISO

- D2 → SCK

- D3 → CS (optional)

- GND → GND

Setup in Software:

- Add SPI decoder.

- Assign:

- MOSI → D0

- MISO → D1

- Clock → D2

- CS (optional) → D3

- Set SPI mode (0 to 3), bit order (MSB first), etc.

What You’ll See:

- SPI data packets.

- Data sent from master to slave (MOSI) and received (MISO).

Use Case: Debug EEPROM or display modules using SPI.

C. I2C (Inter-Integrated Circuit)

Overview:

- 2 wires:

- SDA – Data

- SCL – Clock

- Each device has an address

Wiring:

- D0 → SDA

- D1 → SCL

- GND → GND

Setup in Software:

- Add I2C decoder.

- Assign:

- SDA → D0

- SCL → D1

- No other settings needed (auto-detects data/address).

What You’ll See:

- Start → Address → Read/Write → Data → ACK/NACK → Stop

- Decoded addresses and data bytes.

✅ Use Case: Debug sensors like BMP280, DS1307, OLEDs, etc.

5. Example: Debug I2C Sensor (BMP280)

- Connect logic analyzer:

- D0 → SDA

- D1 → SCL

- GND → GND

- Start PulseView capture.

- Trigger sensor read from microcontroller.

- I2C decoder will show:

- Address:

0x76 - Read/Write:

W - Data:

F4,2F,FC, etc.

- Address:

6. Safety Tips & Best Practices

- ✅ Always connect GND between your circuit and the logic analyzer.

- ⚠️ Only connect to 3.3V or 5V logic — higher voltages can damage the analyzer.

- 📉 Choose a sampling rate at least 10x the clock speed (e.g., 2MHz for 100kHz I2C).

- 🔄 Use short wires to avoid noise and glitches.

- 🧠 Interpret decoded signals to find bugs in your firmware or mismatched settings.

Summary Table

| Protocol | Wires Needed | Pins to Connect | Software Decoder | Notes |

|---|---|---|---|---|

| UART | TX, RX | D0 → TX, D1 → RX | UART | Set baud rate manually |

| SPI | MISO, MOSI, SCK, CS | D0–D3 | SPI | Set SPI mode (0-3) |

| I2C | SDA, SCL | D0 → SDA, D1 → SCL | I2C | Auto-detects most settings |

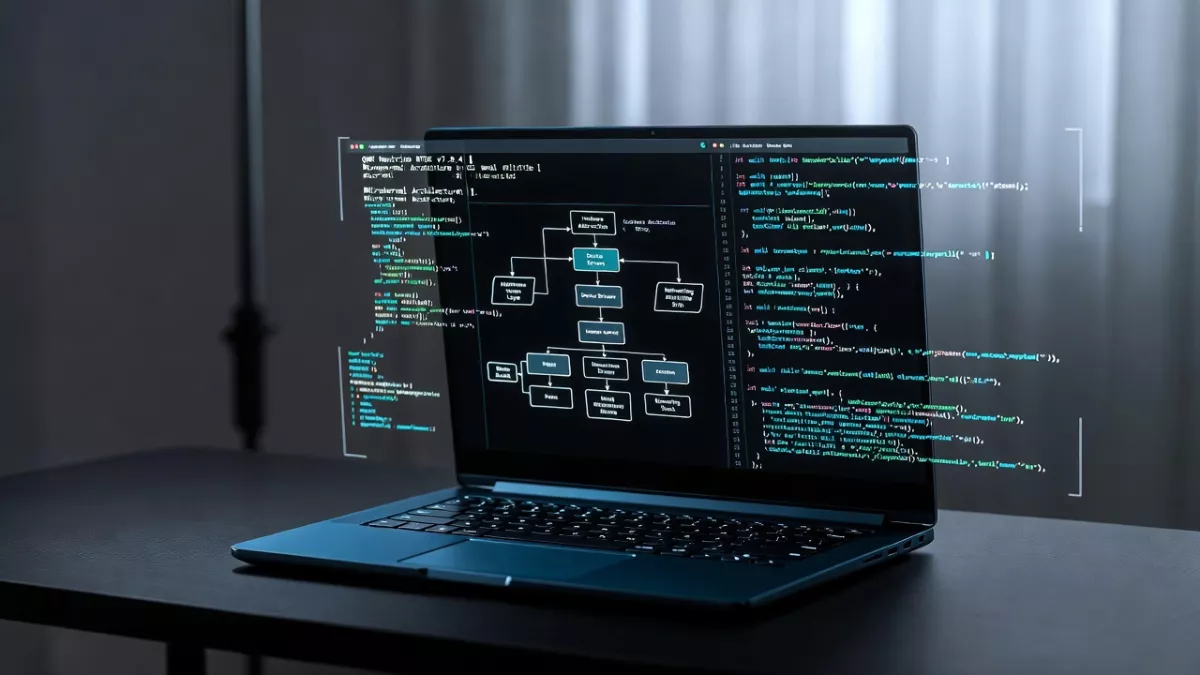

Guide to Using an Oscilloscope

Waveform Analysis, Triggering, Noise Detection

An oscilloscope is a vital tool in electronics for viewing and analyzing electrical waveforms. It allows you to visualize signals in real time, helping you debug circuits, measure signal characteristics, and detect noise.

1. What Is an Oscilloscope?

An oscilloscope (also known as a scope) displays voltage signals over time as waveforms, with time on the x-axis and voltage on the y-axis.

Key Parts:

- Display: Shows the waveform of the signal.

- Probes: Used to connect the oscilloscope to your circuit.

- Controls/Knobs:

- Time Base: Adjusts the time per division (horizontal scale).

- Voltage Scale: Adjusts the voltage per division (vertical scale).

- Trigger: Stabilizes waveforms.

- Position: Shifts the waveform left/right or up/down.

2. Setting Up the Oscilloscope

Step 1: Connect the Probe

- Plug the oscilloscope probe into the probe input on the oscilloscope.

- Black clip goes to GND of your circuit.

- Red probe goes to the signal you’re measuring (e.g., test points, output pins).

Step 2: Turn on the Oscilloscope

- Power up your oscilloscope and ensure it’s properly calibrated.

3. Waveform Analysis: Understanding the Basics

What is a Waveform?

A waveform is a graphical representation of an electrical signal’s variation in voltage over time. It allows you to visually inspect:

- Frequency (how often the wave repeats)

- Amplitude (the height of the wave, showing signal strength)

- Shape (sine, square, triangle, etc.)

What You See on the Screen:

- The oscilloscope plots the voltage (y-axis) against time (x-axis).

- The horizontal axis shows time (e.g., 1ms/div), so you can measure signal period (how long one cycle lasts).

- The vertical axis shows voltage (e.g., 1V/div), letting you see signal amplitude (the peak-to-peak voltage).

Example:

If you’re measuring a sine wave signal, it might look like this:

- Period = time for one complete wave.

- Frequency = 1 / period.

- Amplitude = peak-to-peak height of the wave.

4. Triggering: Stabilizing Your Signal

What is Triggering?

Triggering helps you stabilize repetitive waveforms on the oscilloscope display. Without triggering, the waveform may appear as a blurry jumble, making it hard to measure.

How to Use Triggering:

- Trigger Source: Choose which signal to use for triggering (e.g., CH1 for the signal you’re observing).

- Trigger Level: Set the voltage level at which the oscilloscope will trigger.

- Trigger Mode: Choose between different modes:

- Edge Triggering: Triggers on a rising or falling edge (default mode).

- Pulse Width Triggering: Triggers on a signal that is either too long or too short.

- Video Triggering: Useful for video signals.

When to Use Triggering:

- If your waveform is moving around or not stable, adjust the trigger level until it “locks” the waveform in place.

- Auto mode automatically triggers after some time, but Normal mode waits until a specific signal level is reached.

5. Noise Detection: Identifying Unwanted Signals

What is Noise?

Noise is any unwanted electrical signal that disrupts your intended signal, leading to errors or inaccurate readings.

How to Detect Noise:

- Look for unexpected spikes or irregularities in your waveform.

- Measure and observe how noise affects signal stability:

- Noise can appear as random fluctuations or spikes superimposed on your primary signal.

- It may cause your waveform to be distorted or noisy.

Reducing Noise:

- Use proper grounding: Ensure your circuit and oscilloscope are well-grounded.

- Shielding: Use shielded cables or enclosures to prevent external interference.

- Bandwidth Limiting: Use filters or reduce bandwidth to exclude high-frequency noise.

- Averaging: Some oscilloscopes allow you to average signals, smoothing out noise for better analysis.

6. Practical Tips for Using an Oscilloscope

- Start with low time base (e.g., 1ms/div) to get a clear view of the signal.

- Increase the time base if the signal is too fast to capture (e.g., use 10us/div for high-speed signals).

- Use the trigger to stabilize repetitive waveforms.

- Zoom in and out with the time and voltage controls to inspect different aspects of your signal.

- Use Math Functions: Some oscilloscopes allow you to overlay math functions like adding, subtracting, or averaging waveforms.

7. Summary of Key Controls

| Control | Function |

|---|---|

| Time Base | Controls the time per division (horizontal scale) |

| Voltage Scale | Controls the voltage per division (vertical scale) |

| Trigger Source | Specifies which signal to trigger on (e.g., CH1) |

| Trigger Level | Sets the voltage level that triggers the oscilloscope |

| Position | Shifts the waveform left/right or up/down |

8. Example: Analyzing a Square Wave

Step-by-Step:

- Connect the probe to the square wave generator output.

- Set the time base to 1ms/div.

- Adjust the trigger level to the middle of the square wave.

- Observe the waveform:

- You’ll see a square wave with sharp transitions (rising and falling edges).

- The frequency of the square wave is the rate at which the waveform repeats (e.g., 1kHz).

- Analyze:

- Measure the high and low levels of the wave (voltage).

- Check for symmetry and proper signal integrity.

9. Conclusion: Your Oscilloscope at a Glance

An oscilloscope is a powerful tool for waveform analysis, triggering, and noise detection. By understanding the basic controls and techniques:

- You can measure voltage, frequency, and other properties of your signals.

- Stabilize waveforms using the trigger function.

- Detect and mitigate noise issues in your circuits.

As you practice, you’ll become more comfortable interpreting different waveforms and using the oscilloscope for complex signal analysis.

Using Power Supply and Lab Tools Safely

A Beginner’s Guide to Safe Practices in the Electronics Lab

Working with electronic circuits and equipment can be exciting, but it’s crucial to follow proper safety protocols. Lab tools like power supplies, oscilloscopes, multimeters, and soldering irons are essential for electronics work, but they can also pose risks if used improperly.

This guide will introduce you to safe practices while using power supplies and lab tools, helping you avoid accidents and ensure a safe, productive environment.

1. Power Supply Safety

What Is a Power Supply?

A power supply provides electrical power to your circuits by converting AC (Alternating Current) from a wall outlet into DC (Direct Current) or supplying a specific type of voltage or current needed by your circuit.

Basic Safety Precautions:

a. Know Your Equipment:

- Before using a power supply, read the manual carefully to understand its voltage, current limits, and other features.

- Check connections to ensure everything is wired correctly before turning on the power supply.

b. Set Voltage and Current Limits:

- Always set the voltage and current limits of the power supply before connecting it to the circuit.

- If you’re unsure about the voltage requirements of your circuit, start with a low voltage setting to avoid damage.

c. Use the Right Power Supply:

- Choose the correct power supply type (e.g., DC power supply for DC circuits) and ensure it matches the voltage and current ratings of your circuit.

d. Avoid Overloading:

- Don’t exceed the maximum current limit of the power supply. Overloading can cause the power supply to overheat and potentially damage your circuit or the power supply itself.

e. Turn Off Power Before Making Changes:

- Always turn off the power supply and disconnect the leads before changing any circuit connections or making adjustments to your setup.

f. Use Fuses for Protection:

- Power supplies often have built-in fuses to protect the circuit from overcurrent. Check if the fuse is properly rated, and always replace fuses with the correct type.

g. Grounding:

- Ensure the power supply is properly grounded to avoid electrical shock hazards. A properly grounded setup reduces the risk of short circuits or voltage spikes.

2. Multimeter Safety

What Is a Multimeter?

A multimeter is used to measure voltage, current, and resistance. It’s an essential tool for troubleshooting circuits and verifying correct voltage levels.

Basic Safety Precautions:

a. Check Probes and Leads:

- Inspect the multimeter probes and leads for any damaged insulation before use. Damaged leads can cause short circuits or electrical shocks.

b. Set the Multimeter Correctly:

- Ensure you set the multimeter to the correct function (e.g., voltage, current, resistance) and range. For current measurement, ensure the multimeter is in series with the circuit, not in parallel.

c. Avoid Measuring High Voltage:

- Always use a multimeter rated for high voltage when measuring circuits with voltages above 30V. High voltage circuits require special care, and the multimeter should be rated for those voltages.

d. Never Measure Resistance on Live Circuits:

- Avoid measuring resistance or continuity on circuits that are powered on. Doing so can damage the multimeter and cause electrical hazards.

e. Use Proper Settings for Current:

- When measuring current, break the circuit and connect the multimeter in series. Never set the multimeter to current measurement while it is in parallel with a power source.

3. Soldering Iron Safety

What Is a Soldering Iron?

A soldering iron is a tool used to heat and melt solder to connect electronic components to a circuit board. It’s a crucial tool, but the heat it generates makes it dangerous if used carelessly.

Basic Safety Precautions:

a. Wear Protective Gear:

- Wear protective glasses to shield your eyes from solder fumes and any accidental splashes of molten solder.

- Use heat-resistant gloves if necessary, especially when handling hot components or the soldering iron.

b. Work in a Well-Ventilated Area:

- Soldering fumes can be harmful if inhaled. Always use the soldering iron in a well-ventilated area or, ideally, with a fume extractor.

c. Set the Soldering Iron Down Carefully:

- Always place the soldering iron on a heat-resistant surface or a soldering stand. Never leave it unattended, as it can cause fires or burns if left on an inappropriate surface.

d. Turn Off When Not in Use:

- Always turn off the soldering iron when you’re finished using it, and unplug it when not in use to avoid accidental burns.

4. Oscilloscope and Other Lab Tools Safety

📖 What Is an Oscilloscope?

An oscilloscope is used to visualize and analyze electrical waveforms, such as signals from a microcontroller or sensor. It is a delicate instrument that requires attention to safety.

Basic Safety Precautions:

a. Grounding:

- Ensure that both the oscilloscope and your circuit are properly grounded to avoid electrical shock and ensure accurate measurements.

b. Use Proper Probes:

- Use oscilloscope probes that are rated for the voltage levels you are measuring. Some high-voltage circuits require special probes for safety.

c. Do Not Touch Live Circuitry:

- Avoid touching live circuitry or components while connected to the oscilloscope to prevent shock and short-circuits.

d. Handling Capacitors:

- Discharge capacitors before working with them, as they can hold a charge and give you a shock even when the circuit is powered off.

e. Avoid Overloading:

- Like power supplies, oscilloscopes also have limits for voltage and current. Never exceed the voltage ratings of the oscilloscope probe.

5. General Safety Tips for the Electronics Lab

- Read manuals before using any tool. Understanding the user manual of each device is crucial to ensure safe usage.

- Organize your workspace to reduce clutter. A tidy lab helps avoid accidents, makes tools easier to find, and reduces tripping hazards.

- Use insulated tools when working with electrical circuits to reduce the risk of short circuits and electrical shock.

- Unplug devices when not in use. Always disconnect equipment from power sources before making adjustments.

- Wear safety glasses and gloves as a basic measure when working with hot components or sharp objects.

6. Emergency Preparedness

Even with all the safety precautions, accidents can happen. Here are a few tips to stay prepared:

- Know the location of the emergency shut-off switch in the lab or your workspace.

- Learn basic first aid for electrical burns and shock.

- Have a fire extinguisher nearby, especially when working with soldering irons and other heat-producing tools.

Conclusion: Stay Safe and Have Fun

Using power supplies and lab tools is an essential part of working in electronics, but safety should always come first. By following the guidelines outlined in this article, you’ll minimize risks and create a safer environment for yourself and others. Remember, always respect the tools and circuits you work with, and don’t hesitate to ask for help or advice from more experienced individuals when needed.

You can also Visit other tutorials of Embedded Prep

- What is eMMC (Embedded MultiMediaCard) memory ?

- Top 30+ I2C Interview Questions

- Bit Manipulation Interview Questions

- Structure and Union in c

- Little Endian vs. Big Endian: A Complete Guide

- Merge sort algorithm

Special thanks to @mr-raj for contributing to this article on EmbeddedPrep

Mr. Raj Kumar is a highly experienced Technical Content Engineer with 7 years of dedicated expertise in the intricate field of embedded systems. At Embedded Prep, Raj is at the forefront of creating and curating high-quality technical content designed to educate and empower aspiring and seasoned professionals in the embedded domain.

Throughout his career, Raj has honed a unique skill set that bridges the gap between deep technical understanding and effective communication. His work encompasses a wide range of educational materials, including in-depth tutorials, practical guides, course modules, and insightful articles focused on embedded hardware and software solutions. He possesses a strong grasp of embedded architectures, microcontrollers, real-time operating systems (RTOS), firmware development, and various communication protocols relevant to the embedded industry.

Raj is adept at collaborating closely with subject matter experts, engineers, and instructional designers to ensure the accuracy, completeness, and pedagogical effectiveness of the content. His meticulous attention to detail and commitment to clarity are instrumental in transforming complex embedded concepts into easily digestible and engaging learning experiences. At Embedded Prep, he plays a crucial role in building a robust knowledge base that helps learners master the complexities of embedded technologies.