Nordic Semiconductor has launched the nPM1304, an ultra-low power power management IC (PMIC) designed specifically for compact, battery-operated devices. This advanced PMIC offers precise voltage regulation, efficient USB-C input support, and an innovative model-based fuel gauging system that accurately monitors battery state of charge while minimizing power consumption. Ideal for next-generation wearables and sensor applications, the nPM1304 delivers comprehensive battery management and system-level features, making it a perfect solution for miniaturized electronics demanding both power efficiency and reliability.

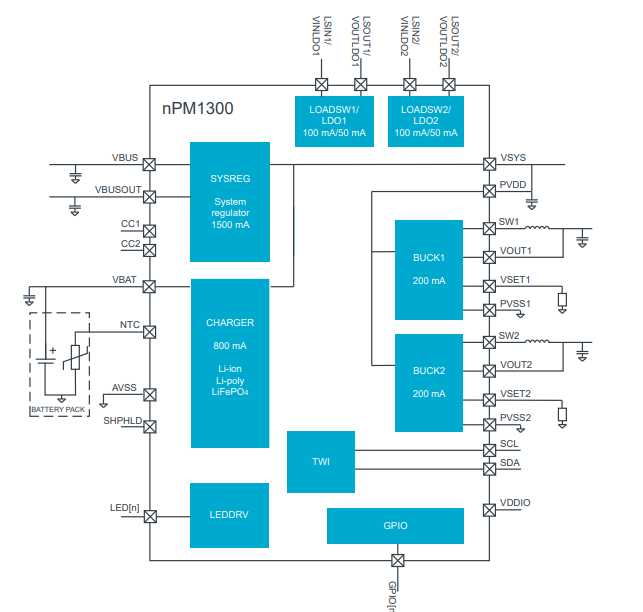

Nordic Semiconductor has unveiled its latest power management integrated circuit (PMIC), specifically engineered for compact electronic devices powered by small-capacity batteries. The new PMIC, named nPM1304, builds on the success of its predecessor, the nPM1300, and offers advanced power efficiency tailored for next-generation wearable technology and sensor applications.

Next-Generation PMIC Designed for Miniaturized Battery-Powered Devices

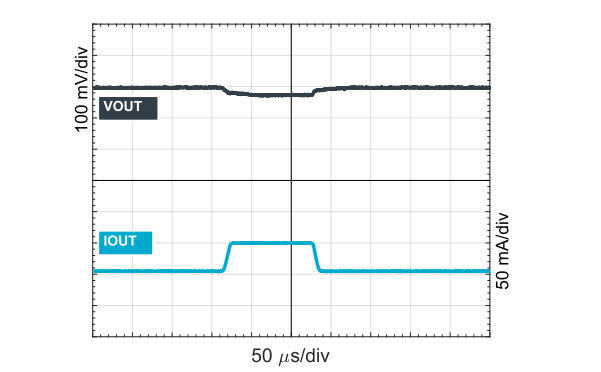

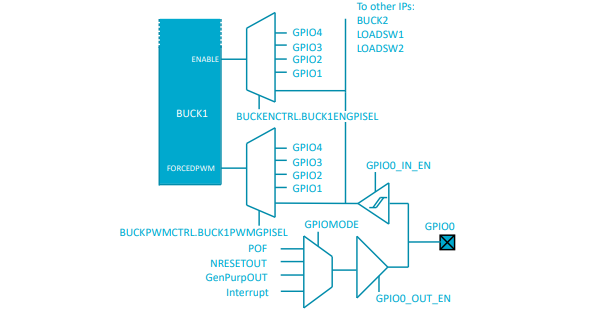

The nPM1304 power management IC is designed to meet the growing demand for compact and energy-efficient solutions in the wearables and IoT market. It delivers four independently controlled power rails via two 200mA buck regulators and two 100mA load switches (which can also be configured as 50mA LDOs). Each power rail offers precise voltage regulation from 1.0 V up to 3.3 V, enabling versatile application support.

Supporting USB-C input, the nPM1304 includes an integrated input regulator capable of handling 4.0 V to 5.5 V with a 1.5 A current limit and tolerates transient voltages up to 22 V, making it highly adaptable to varying power sources.

[ VBUS ] ──► [ SYSREG ]

│

▼

VSYS

│

┌────────────────┴─────────────┐

│ │

│ │

│ [ CHARGER ]

│ │

│ +----------+----------+

│ │ │

│ [ Battery ] [ NTC ]

│ │

│ [ SHPHLD ]

│ │

│ [ LEDDRV ]

│

│

▼

[ BUCK1 ] ──► VOUT1

│

[ VSET1 ]

[ BUCK2 ] ──► VOUT2

│

[ VSET2 ]

[ LDO1 / LOADSW1 ] ──► LDO1_VOUT

[ LDO2 / LOADSW2 ] ──► LDO2_VOUT

[ GPIO ]

[ TWI (I2C) ]

│

[SCL] [SDA]

Innovative Model-Based Fuel Gauging for Accurate Battery Monitoring

One of the standout features of the nPM1304 PMIC is its model-based fuel gauging system. Unlike traditional coulomb counting methods that require continuous power consumption and recalibration, Nordic’s approach estimates the battery state of charge by analyzing voltage, current, and temperature data. This results in highly accurate battery monitoring with significantly reduced power consumption — drawing just 8 µA during active operation and zero current in sleep mode. This ultra-low power design is especially beneficial for devices with stringent energy budgets.

Comprehensive Battery Management with Programmable Charging

The device supports a linear battery charger compatible with multiple chemistries, including Li-ion, Li-polymer, and LiFePO₄. Programmable charge currents range from 4 mA to 100 mA, and the termination voltage is adjustable between 3.5 V and 4.65 V, enabling flexible charging profiles tailored to specific battery types.

Additional system-level features include watchdog and boot timers, power loss warning, configurable hard reset functions, recovery from failed boots, and a user-friendly I²C interface for system configuration. Developers also benefit from five general-purpose I/Os and three LED drivers integrated within the chip.

Why Model-Based Fuel Gauging Outperforms Traditional Coulomb Counting

Traditional coulomb counting estimates battery charge by measuring the current flowing in and out of the battery using sense resistors and integrating the results over time. Although effective, this method is prone to cumulative errors and requires periodic recalibration, which can be impractical for small devices with low and irregular current draws.

Moreover, coulomb counting circuitry demands continuous power, often consuming a notable fraction of the device’s limited energy budget. Nordic’s model-based fuel gauge sidesteps these issues by employing a dynamic battery model that efficiently interprets sensor data, reducing energy use while maintaining state-of-charge accuracy.

Meeting Industry Demands for Compact and Efficient Power Management

The nPM1304 addresses the growing need for compact, ultra-efficient power management ICs that support the increasing miniaturization of wearable and sensor devices. Nordic Semiconductor is now offering samples of this PMIC to developers looking to optimize power consumption in their battery-operated embedded systems.

Advantages of nPM1300 PMIC

✅ Highly Integrated Solution

- Combines charger, regulators, LED drivers, and GPIO in a single chip → reduces PCB space and BOM cost.

✅ Battery Charger Included

- Supports Li-ion, Li-poly, and LiFePO4 batteries.

- Integrated battery charging (up to 800 mA) eliminates need for separate charger ICs.

✅ Low Power Consumption

- Suitable for battery-operated designs.

- System regulator (SYSREG) and low quiescent current help extend battery life.

✅ Multiple Outputs

- Two buck converters and two LDOs/Load switches allow powering different rails with separate voltages.

- Flexible for different peripherals (MCU, sensors, radios).

✅ I²C Interface (TWI)

- Programmable control of output voltages and other parameters → dynamic power management.

- Enables MCU or SoC to adjust power rails in software.

✅ Integrated LED Drivers

- Useful for status indicators or backlighting without extra driver ICs.

✅ Compact Solution

- Smaller PCB footprint ideal for wearable, IoT, and portable devices.

Disadvantages of nPM1300 PMIC

❌ Current Limitations

- Buck converters limited to 200 mA → insufficient for high-power loads like large displays or motors.

- LDO/Load switches limited to 100 mA / 50 mA.

❌ Complexity in Configuration

- Requires software configuration via TWI → not purely hardware plug-and-play.

- Might add development time for tuning voltages and power sequences.

❌ Limited Battery Chemistries

- Although supporting common battery types, not suitable for NiMH, NiCd, or other less-common chemistries.

❌ Cost

- Integrated PMICs can be more expensive than discrete solutions in ultra-low-cost designs.

Real-Time Applications

The nPM1300 is perfect for low-power embedded and portable applications requiring power efficiency and small form factor. Real-time examples:

✅ Wearable Devices

- Smartwatches

- Fitness bands

- Medical patches

✅ IoT Devices

- Wireless sensors

- Smart home devices

- Asset tracking tags

✅ Portable Medical Devices

- Glucose monitors

- Portable ECG devices

✅ Wireless Audio

- Earbuds

- Bluetooth headsets

✅ Compact Industrial Devices

- Portable measurement tools

- Handheld scanners

✅ Remote Controls / Smart Tags

- Low-power BLE or proprietary RF remotes

- RFID/NFC-enabled tags

Mr. Raj Kumar is a highly experienced Technical Content Engineer with 7 years of dedicated expertise in the intricate field of embedded systems. At Embedded Prep, Raj is at the forefront of creating and curating high-quality technical content designed to educate and empower aspiring and seasoned professionals in the embedded domain.

Throughout his career, Raj has honed a unique skill set that bridges the gap between deep technical understanding and effective communication. His work encompasses a wide range of educational materials, including in-depth tutorials, practical guides, course modules, and insightful articles focused on embedded hardware and software solutions. He possesses a strong grasp of embedded architectures, microcontrollers, real-time operating systems (RTOS), firmware development, and various communication protocols relevant to the embedded industry.

Raj is adept at collaborating closely with subject matter experts, engineers, and instructional designers to ensure the accuracy, completeness, and pedagogical effectiveness of the content. His meticulous attention to detail and commitment to clarity are instrumental in transforming complex embedded concepts into easily digestible and engaging learning experiences. At Embedded Prep, he plays a crucial role in building a robust knowledge base that helps learners master the complexities of embedded technologies.