If you’ve ever wondered how your phone records your voice, how a microcontroller reads sensor values, or how digital scales measure weight so accurately, the answer hides in a tiny but powerful circuit: the ADC analog to digital converter.

Today, let’s break down what is an ADC analog to digital converter, how it works, why we use it, and how it fits into real electronics like Arduino, Raspberry Pi, audio systems, and precision devices.

What Is an ADC Analog to Digital Converter?

Let’s start with the simplest explanation.

An ADC analog to digital converter is an electronic device that takes real-world analog signals (like temperature, sound, pressure, or light) and converts them into digital values that a microcontroller or computer can understand.

That’s the entire adc analog to digital converter definition.

Think of it like this:

- Your voice, temperature, or light is smooth and continuous → analog

- Computers only understand numbers → digital

The ADC is the translator between these two worlds.

Why Do We Need an ADC? What Does an Analog to Digital Converter ADC Do?

You interact with ADCs more than you realize. They are literally everywhere:

- In mobile phones (for audio recording)

- In digital thermometers

- In Arduino sensor projects

- In Bluetooth speakers

- In digital weighing scales

- In cars, drones, and IoT devices

So when someone asks:

“What does an analog to digital converter ADC do?”

The answer is simple:

It converts continuous analog signals into readable digital numbers.

For example:

- A temperature sensor gives 0–3.3V

- The microcontroller reads it as 0–4095 (12-bit ADC)

Useful, right?

ADC Analog to Digital Converter Basics

Before going deeper, let’s understand the basics:

Inputs to ADC

The input is always an analog voltage, usually in the range:

- 0–5V

- 0–3.3V

- 0–1.1V

(depending on the device)

Outputs from ADC

The output is a digital number.

The number of bits decides the resolution:

- 8-bit → 0 to 255

- 10-bit → 0 to 1023

- 12-bit → 0 to 4095

- 24-bit → 0 to 16,777,215

Higher bits → more accuracy.

How Does an ADC Analog to Digital Converter Work?

Now let’s discuss how ADC actually works inside.

When you ask:

“How does an ADC analog to digital converter work?”,

the general idea is this:

The ADC chops the analog signal into tiny steps and assigns each step a number.

That’s it.

But here’s the process in slightly more detail:

Sampling

The ADC takes small “snapshots” of the analog signal at regular intervals.

Like snapping photos quickly—this is called sampling frequency.

Quantization

Each sample is mapped to the closest digital level (step).

Encoding

The step number is converted into binary.

This is how ADC converts analog to digital.

Types of ADC

There are many types of ADCs. Let me quickly explain the popular ones.

Successive Approximation Register (SAR ADC)

Very common in microcontrollers.

Fast and accurate.

Sigma-Delta ADC

Used in audio systems and high-precision devices.

Extremely accurate but slower.

Flash ADC

Super fast, used in oscilloscopes.

Dual-Slope ADC

Very accurate but slow.

Used in digital multimeters.

When someone searches for the best ADC analog to digital converter, it often depends on:

- Speed

- Accuracy

- Application

- Noise tolerance

There’s no single “best”—it depends on use case.

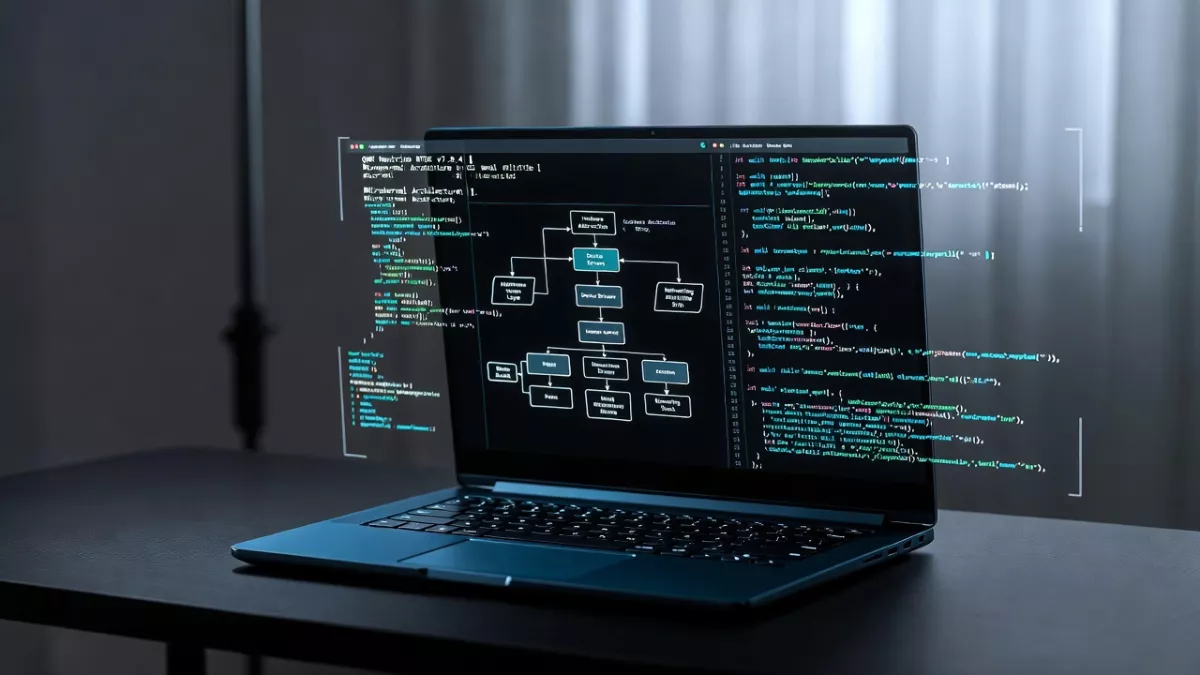

ADC Analog to Digital Converter Block Diagram

A typical analog to digital converter ADC block diagram includes:

- Sample-and-hold circuit

- Comparator

- Reference voltage

- Quantizer

- Encoder

You don’t need to memorize this.

Just remember that these blocks help the ADC measure voltage and convert it into numbers.

Real Examples of ADC in Everyday Tech

Example 1: Phone microphone → analog to digital audio converter ADC

Your voice is analog → microphone picks it → ADC converts it → smartphone records it.

Example 2: Arduino reading sensors

The analog to digital converter ADC Arduino feature lets Arduino boards measure:

- temperature

- sound

- distance

- humidity

- gas levels

Example 3: Audio Systems

Brands like Blustream ADC analog to digital audio converter convert analog TV audio into digital formats.

Example 4: Weighing Scales (24-bit ADC)

A 24 bit analog to digital converter ADC for weigh scales is extremely precise.

It is used in:

- electronic weighing machines

- lab-grade measuring devices

- industrial load cell systems

Why 24 bits?

Because you get over 16 million steps, allowing super small measurements.

Popular ADC Modules You Can Use

Here are some practical ADC modules.

1. MCP3008 ADC Analog to Digital Converter

One of the most popular ADC chips in the world.

It offers:

- 8 channels

- 10-bit resolution

- SPI interface

- Works perfectly with Raspberry Pi

If your board has no built-in ADC (like Raspberry Pi), the mcp3008 adc analog to digital converter is often the first choice.

2. ADS1115 (16-bit ADC)

Very accurate

I2C interface

Used with sensors needing high precision.

3. HX711 (24-bit ADC)

Used for weighing scales and load cells.

4. Simple Module ADC Analog to Digital Converter Boards

These are plug-and-play ADC breakout boards sold online.

People often search for module ADC analog to digital converter because these small boards are easy to interface.

ADC Interfacing (How to Connect an ADC to a Microcontroller)

The process is simple.

When someone searches for analog-to-digital converter (ADC) interfacing, they usually want to know:

How to connect power

VCC → 3.3V or 5V

GND → Ground

How to connect analog input

Sensor output → ADC input pin (A0)

How to read digital data

Using protocols:

- SPI

- I2C

- UART

- or direct analog pins (for internal ADCs)

Example: Interfacing MCP3008

MOSI → DIN

MISO → DOUT

CLK → Clock

CS → Chip Select

Then read values through SPI.

ADC in Arduino

When someone asks:

analog to digital converter ADC Arduino,

they usually want to read sensor values.

Arduino Uno has:

- 10-bit ADC

- 6 analog input pins (A0 to A5)

So a voltage between 0–5V becomes a number between 0 and 1023.

Example:

- 2.5V → approx. 512

- 1V → approx. 205

- 4V → approx. 820

You simply write:

int sensor = analogRead(A0);

That’s it.

ADC for Audio

Audio needs accurate and clean conversions.

So when people search for:

- analog to digital audio converter ADC

- adc analog to digital audio converter

- Blustream ADC analog to digital audio converter

they want devices that convert analog audio signals (RCA or AUX) into digital outputs like:

- optical

- coaxial

- USB

These converters use Sigma-Delta ADCs, which are excellent for sound quality.

24-Bit ADC Explained (Why So Accurate?)

A 24 bit analog to digital converter ADC is extremely sensitive.

It is used in:

- weigh scales

- precision sensors

- medical equipment

- lab devices

For example, a 24 bit analog to digital converter ADC for weigh scales can detect even very small weight changes—perfect for digital kitchen scales or industrial load cells.

How ADC Converts Analog to Digital

Let’s simplify it even more.

Imagine a staircase.

- The analog signal is a smooth ramp

- The ADC “snaps” that ramp to the nearest stair

- Each stair is a number (digital value)

The more stairs (bits), the smoother and more accurate the conversion.

That’s literally how ADC converts analog to digital.

What Makes the Best ADC Analog to Digital Converter?

There’s no single best ADC.

It depends on what you need.

For beginners

MCP3008 or ADS1115

For audio

Sigma-Delta ADC

Blustream converters

For high accuracy

24-bit ADC (HX711)

For speed

Flash ADCs

For general use

Built-in microcontroller ADC

Choosing the Right ADC for Your Project

Here are quick recommendations:

For Arduino Sensors

Use the internal ADC or ADS1115 for higher accuracy.

For Raspberry Pi

Use MCP3008 because Pi has no ADC.

For Audio

Use a proper analog to digital audio converter ADC.

For Weighing Machines

Use HX711 (24-bit).

For Industrial Applications

Use Sigma-Delta ADCs.

Common Mistakes Beginners Make With ADCs

Here are pitfalls beginners face:

Wrong voltage levels

Using a 5V sensor with a 3.3V ADC → damaged chip.

Noise issues

Long wires increase noise.

Use shielding and filtering.

Wrong reference voltage

If reference is unstable → bad readings.

Not averaging readings

Sensors fluctuate; averaging helps.

Practical Tips for Perfect ADC Readings

- Keep sensor wires short

- Use capacitors for filtering

- Use proper grounding

- Choose the right ADC resolution

- Calibrate sensors

- Use differential inputs for noisy environments

Summary

If you’ve made it this far, you now fully understand:

- what is an ADC analog to digital converter

- how it works

- why it’s essential in electronics

- how to choose the right ADC

- how ADC helps in audio, Arduino, sensors, and weighing machines

In simple words:

ADCs help our digital devices understand the real world.

That’s why they are at the heart of every modern electronic system—from phones to IoT devices to audio equipment.

ADC Interview Question

BASIC LEVEL (Fundamentals)

1. ADC Basics

- What is an ADC?

- Why do we need an ADC?

- What is the difference between analog and digital signals?

- What does sampling mean?

- What is quantization?

2. ADC Definitions & Terminology

- Resolution of an ADC

- Sampling rate

- LSB & MSB

- Reference voltage

- Input range

- Digital output format (binary, two’s complement, etc.)

3. ADC Types (Basic Understanding)

- SAR ADC

- Flash ADC

- Sigma-Delta ADC

- Dual-slope ADC

- Pipeline ADC (basic explanation)

MEDIUM LEVEL (Practical + Technical)

4. ADC Working & Concepts

- How does an ADC convert analog to digital?

- Explain sampling theorem (Nyquist).

- What is aliasing and how to avoid it?

- What is SNR and why does it matter?

- What affects ADC accuracy?

- Difference between precision and accuracy?

5. ADC Specifications

Interviewers often check if you understand datasheets:

- ENOB (Effective Number of Bits)

- DNL (Differential Nonlinearity)

- INL (Integral Nonlinearity)

- Offset error & Gain error

- Conversion time & throughput

- ADC clock and sample-and-hold circuit

6. Microcontroller-Based ADC

- How ADC works in Arduino / STM32 / ESP32

- Single-ended vs differential ADC input

- How to use internal reference voltage

- What is ADC calibration?

- What happens if the input exceeds Vref?

7. ADC Noise & Errors

- Sources of ADC noise

- How to reduce ADC noise

- Importance of grounding & shielding

- Analog vs digital ground separation (AGND / DGND)

- Power supply noise effect on ADC

ADVANCED LEVEL (Industry-Grade Knowledge)

8. ADC Architecture Deep Dive

- SAR working in detail

- Sigma-delta modulation and decimation filters

- Flash ADC advantages/disadvantages

- Pipeline ADC stages

- Oversampling and noise shaping

9. ADC in Real Applications

- Using ADC for audio input

- ADC for weight measurement (24-bit HX711)

- ADC for sensors (temp, gas, pressure, etc.)

- ADC in automotive ECUs

- ADC in medical devices

10. ADC Interfacing Protocols

- SPI-based ADC (example: MCP3008, ADS1118)

- I2C-based ADC (example: ADS1115)

- Parallel ADCs

- ADC DMA usage (STM32, ESP32)

11. Filtering Techniques

- Analog filtering (RC low-pass)

- Digital filtering:

- Moving average

- FIR/IIR basics

- Median filtering

- Anti-aliasing filters (AAF)

EXPERT LEVEL (System + Mathematical + Design)

12. ADC Design Challenges

- Designing ADC input stage

- Buffer op-amp requirements

- Designing PCB for high-resolution ADC

- Ground loops & layout rules

- Why 24-bit ADC does not guarantee 24-bit accuracy

13. FFT & Signal Processing Questions

- Using ADC output in FFT

- How sampling rate affects frequency resolution

- Aliasing & folding

- Windowing

14. High-Speed ADC Questions

- Requirements for RF ADCs

- Aperture jitter

- Track-and-hold design

15. Safety & Automotive Focus

- ADC diagnostics in automotive

- Redundant ADC channels

- Safety integrity levels (ASIL)

- Monitoring Vref for safety

16. ADC Coding Questions

- Write code to read ADC value (C/C++/Arduino/STM32)

- Convert ADC value to voltage

- Calibrate ADC in code

- Using ADC interrupts / DMA

Frequently Asked Questions — What is an ADC (Analog to Digital Converter)

1. What is an ADC analog to digital converter?

An ADC analog to digital converter is an electronic component that converts a continuous analog voltage into a discrete digital number. Put simply, it translates real world signals like sound, light, or temperature into numbers your microcontroller or computer can understand. This is the core answer to the question what is an adc analog to digital converter.

2. How does an ADC analog to digital converter work?

The ADC works in three main steps: sampling, quantization, and encoding. First it samples the analog signal at regular intervals. Then it maps each sample to the nearest digital level, called quantization. Finally it encodes that level into binary. This process — in short — explains how an adc analog to digital converter works and why sampling rate and resolution matter.

3. What does an analog to digital converter ADC do in an audio system?

In audio systems the analog to digital audio converter ADC converts microphone or line-level signals into digital audio streams. High quality audio ADCs use sigma-delta designs to reduce noise and give good dynamic range. Brands and modules often marketed as analog to digital audio converter are optimized for sample rate and bit depth so music and voice sound natural when recorded or streamed.

4. Which ADC module should I use with a Raspberry Pi or microcontroller?

If your board lacks a built-in ADC, common choices include the MCP3008 ADC analog to digital converter for Raspberry Pi and the ADS1115 for higher precision. The MCP3008 is an SPI based 8-channel 10-bit module that is easy to wire and code. Choose the module ADC analog to digital converter based on required channels, bit depth, and interface like SPI or I2C.

5. What are ADC types and which one is best for my project?

Popular types are SAR, sigma-delta, flash, and dual-slope. SAR ADCs are common in microcontrollers because they balance speed and accuracy. Sigma-delta ADCs are excellent for audio and precision measurements. Flash ADCs are fastest but expensive. The best ADC analog to digital converter depends on your needs: speed, resolution, and noise tolerance are the deciding factors.

6. How do I read ADC values on Arduino?

On Arduino use the built-in analogRead function to read an analog pin. Arduino Uno has a 10-bit ADC so analogRead returns values from 0 to 1023. For more precision you can use external modules or boards with 12-bit and 16-bit ADCs. This shows how analog to digital converter ADC Arduino code maps voltages to digital numbers.

7. What is shown in an analog to digital converter ADC block diagram?

A typical analog to digital converter ADC block diagram includes a sample-and-hold, reference voltage, comparator or modulator, quantizer, and encoder. The sample-and-hold captures the input voltage long enough for conversion. The reference sets the full-scale range. Seeing the block diagram helps you understand signal flow and where noise or errors can enter the system.

8. Can I use a 24 bit analog to digital converter ADC for weigh scales?

Yes. A 24 bit analog to digital converter ADC is commonly used for weight measurement because the extra resolution lets you detect very small changes in load cells. Modules like the HX711 are popular for hobby and commercial weigh scales. For industrial or lab scales you may pair a 24-bit ADC with careful mechanical calibration and stable reference voltages.

9. How does ADC resolution affect accuracy and noise?

Resolution determines the number of digital steps an ADC can produce. Higher bit ADCs give smaller steps and the potential for better accuracy. But resolution does not guarantee accuracy if the system has noise, poor reference voltage, or bad grounding. That is why design, shielding, and filtering are as important as bit depth for precise measurements.

10. What is the difference between analog to digital audio converter and general purpose ADC?

An analog to digital audio converter ADC is optimized for audio characteristics like low distortion, suitable sample rates, and anti-alias filtering. General purpose ADCs may prioritize other metrics, such as speed or low power. If you are building a music recorder or streaming device, pick an ADC designed for audio to preserve fidelity.

11. How do I interface an ADC with my microcontroller or single board computer?

Interfacing depends on the ADC interface: native ADC pins, SPI, or I2C are common. For SPI modules like MCP3008 connect MOSI, MISO, CLK and CS and use the SPI library. For I2C ADCs like ADS1115 set the device address and read registers. Good practice includes using common ground, stable reference voltage, and optional input buffering to protect and stabilize signals.

12. How can I improve ADC readings in noisy environments?

Use shielding and short wires, add decoupling capacitors near the ADC supply pins, use a low impedance source or buffer amplifier, and apply simple digital filtering like averaging or moving average in software. Differential ADC inputs can also reject common mode noise. These steps make readings more stable whether you are using a sensor module ADC analog to digital converter or an onboard ADC.

Mr. Raj Kumar is a highly experienced Technical Content Engineer with 7 years of dedicated expertise in the intricate field of embedded systems. At Embedded Prep, Raj is at the forefront of creating and curating high-quality technical content designed to educate and empower aspiring and seasoned professionals in the embedded domain.

Throughout his career, Raj has honed a unique skill set that bridges the gap between deep technical understanding and effective communication. His work encompasses a wide range of educational materials, including in-depth tutorials, practical guides, course modules, and insightful articles focused on embedded hardware and software solutions. He possesses a strong grasp of embedded architectures, microcontrollers, real-time operating systems (RTOS), firmware development, and various communication protocols relevant to the embedded industry.

Raj is adept at collaborating closely with subject matter experts, engineers, and instructional designers to ensure the accuracy, completeness, and pedagogical effectiveness of the content. His meticulous attention to detail and commitment to clarity are instrumental in transforming complex embedded concepts into easily digestible and engaging learning experiences. At Embedded Prep, he plays a crucial role in building a robust knowledge base that helps learners master the complexities of embedded technologies.